Application

- Specifically designed for laboratories situated in urban areas

- Meeting pollution control requirements

- Prevention of re-entry of contaminants in the laboratory

- Effective option to a wet scrubber

Certification by INTERTEK

Aero Dry Scrubber has been tested and certified by Intertek.

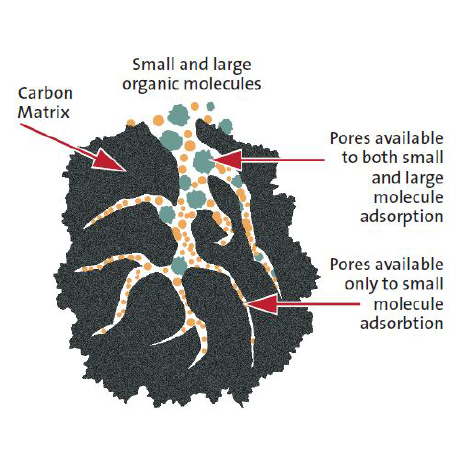

Carbon Filter Basics

It produces millions of pores of molecular dimension that make up a great surface area with a ratio probably larger than 2,000 m2 per gram of activated carbon.

Proactively responding to the challenges for environmental protection

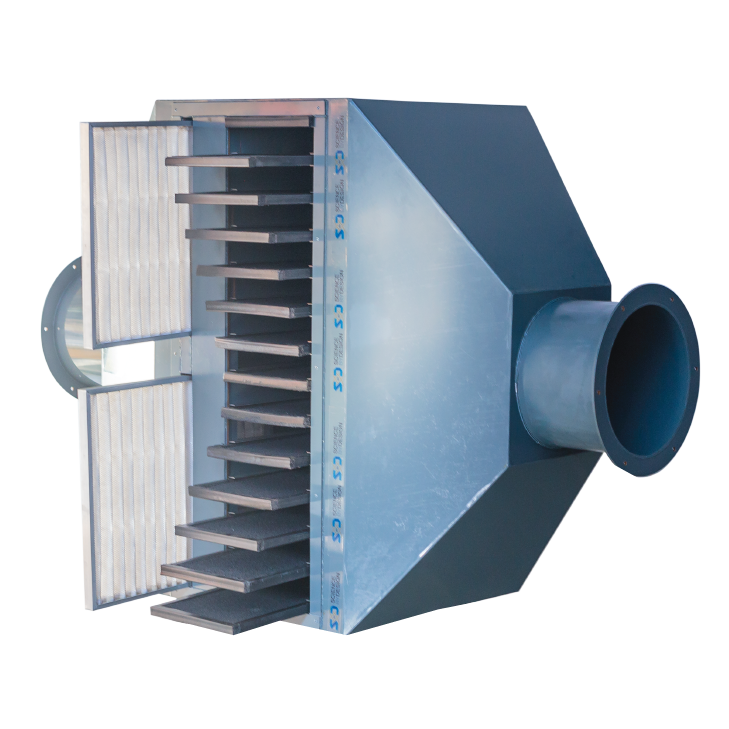

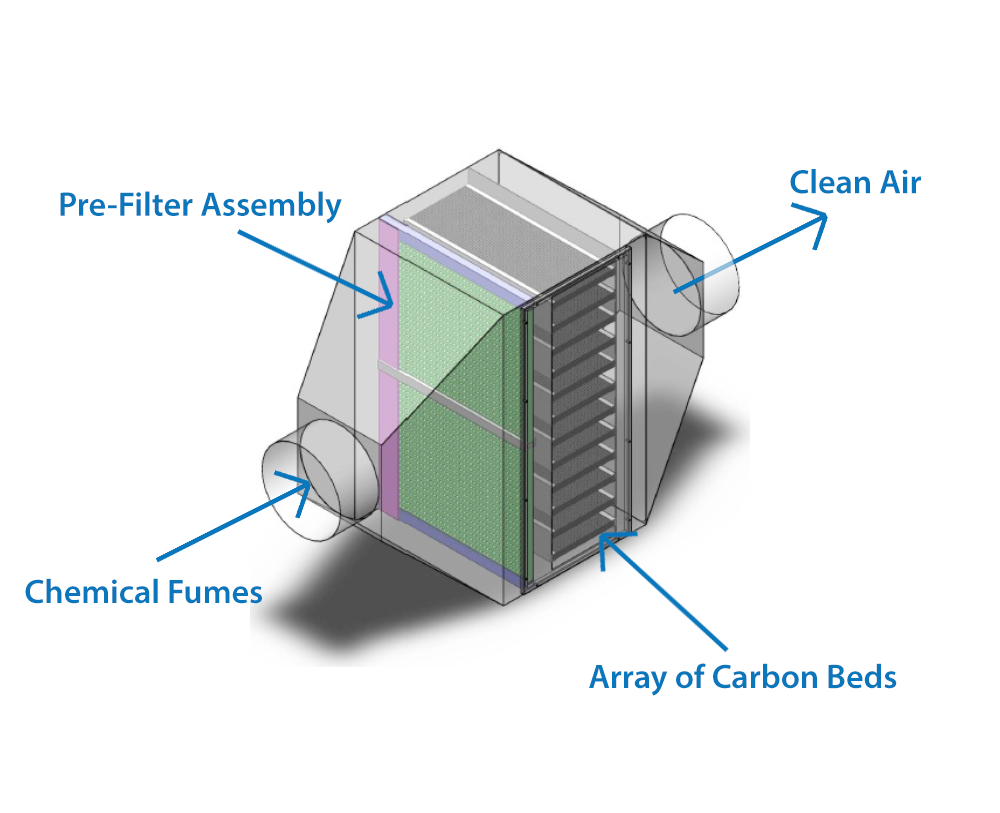

- Aero Dry Scrubber was specifically designed for research laboratories having multiple fume hoods. Due to its high efficiency, it not only meets pollution control requirements but also prevents re-entry of chemical fumes back into the laboratory.

- 25% reduced energy consumption as compared to wet scrubber, makes this a favourite product for companies aiming at energy efficiency. Also it does not require water as a media.

- Furthermore, lightweight makes it quick to install, and unique design makes it easy to maintain.

Award won by Aero Dry Scrubber at CPhI India 2018

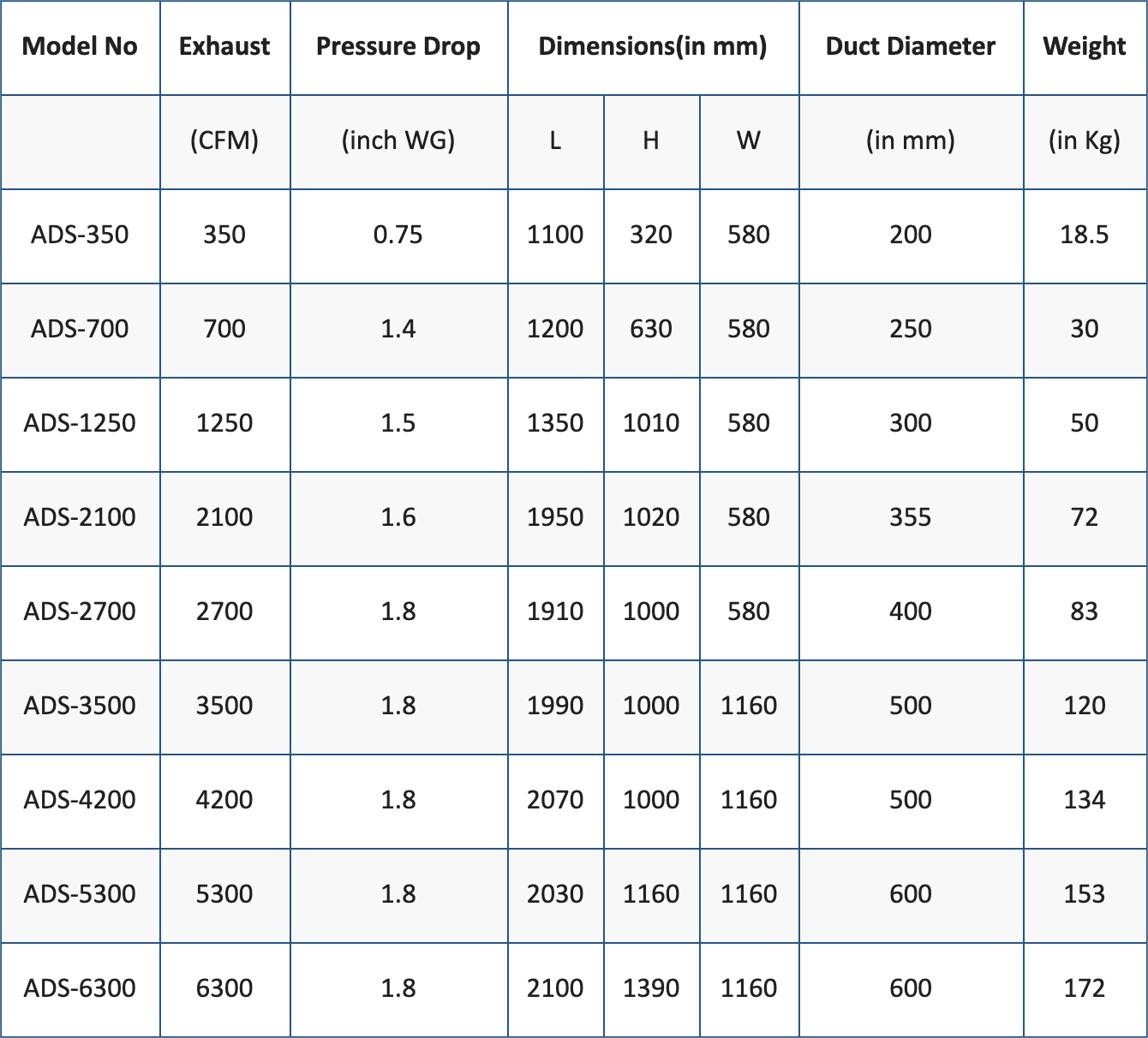

Aero Models

Advantages of Aero Dry Scrubber over Wet Scrubber

| Wet scrubber | Dry scrubber | Advantage | |

|---|---|---|---|

| 1 | 3′-4″ pressure drop | 1′-1.5″ pressure drop | Less running cost |

| 2 | High capacity blower | Low capacity blower | Blower energy saving by 30-35% |

| 3 | Re-circulation pump & back up pump required | Not required | Significant energy savings |

| 4 | Dead load on terrace- 3 to 4 tons | Dead load- 25 kg to 150 kg | No floor stregthening is required, cost saved |

| 5 | ETP & drain line required | Not required | No need to run drain lines till ETP, no leakage |

| 6 | Moving parts | No moving parts | No maintenance required |

| 7 | No indication for functionality | Filter Saturation indication | Indication for performance check |

| 8 | Alkali dosing & PH monitoring required | Acid fumes are neutralized internally due to specially impregnated alkali, so no dosing needed. | Alkali addition & sludge removal eliminated. |

| 9 | Alkali replacement – frequent, PP rings replacement once in 5 years | Carbon filter plates replacement: 1.5-2 years, depending on usage. | Easy to replace. |

| 10 | No filteration of dust particles | Pre-filter installed for dust particles | Increases life of scrubber. |

| 11 | Installation: 4-5 days | 1-2 days | Less downtime, can be installed on weekends too. |

Chemical Adsorption Chart for 228 Chemicals

* Separate filter available for dedicated chemical filtration

Acetic anhydride, Acrylic acid, Acrylonitrile, Adhesives, Allyl chloride, Amyl acetate, Amyl alcohol, Amyl ether, Aniline, Antiseptics, Asphalt fumes, Benzene, Body odour, Bromine, Butanone, Butyl acetate, Butyl alcohol, Butyl cellosolve, Butyl chloride, Butyl ether, Butyric acid, Camphor, Caprylic acid, Carbolic acid, Carbon disulphide, Carbon tetrachloride, Cellosolve acetate, Chlorobenzene, Chlorobutadiene, Chloroform, Chloronitropropane, Chloropicrin, Cigarette smoke, Citrus and other fruits, Cleaning compounds, Creosote, Cresol, Cyclohexane, Cyclohexanol, Cyclohexanone, Cyclohexene, Dead animals, Decane, Detergents, Dibromoethane, Dichlorobenzene, Dichlorodifluoromethane, Dichloroethane, Dichloroethylene, Dichloroethyl ether, Dichloronitroethane, Dichloropropane, Dichlorotetrafluoroethane, Dicyclopentadiene, Diesel fumes, Diethyl ketone, Dimethyl aniline, Dimethyl sulphate, Dioxane, Dipropyl ketone, Epichlorohydrin, Ethyl acetate, Ethyl acrylate, Ethyl benzene, Ethyl bromide, Ethyl silicate, Ethylene chlorohydrin, Ethylene dichloride, Fertilizer, Fish odours, Food aromas, Freon 11, Freon 12, Freon 113, Gasoline, Heptane, Heptylene, Hexanol, Hexanone, Hospital odours, Ide, Iodine, Iodoform, Isopropyl acetate, Isopropyl alcohol, Isopropyl chloride, Isopropyl ether, Kerosene, Ketone, Kitchen odours, Krypton delay, Lactic acid, Liquid fuels, Liquor odours, Lubricating oils and greases, Lysol, Menthol, Mercaptans (large molecules), Mesityl oxide, Methyl acrylate, Methyl butyl ketone, Methyl cellosolve, Methyl cellosolve acetate, Methyl chloroform, Methyl cyclohexane, Methyl cyclohexanol, Methyl cyclohexanone, Methyl ethyl ketone, Methyl glycol, Methyl isobutyl ketone, Methyl methacrylate ester, Methylene chloride, Monochlorobenzene, Monofluorotrichloromethane, Naphtha, Naphthalene, Nicotine, Nitro benzenes, Nitro ethane, Nitro propane, Nitroglycerine, Nonane, Octane, Octene, Ozone, Palmitic acid, Paper deteriorations, Pentanone, Perchloroethylene, Pesticides, Phenol, * Poison gases, Propionic acid, Propyl acetate, Propyl alcohol, Propyl chloride, Propyl ether, Propyl mercaptan, Styrene monomer, Tar, Tetrachloroethane, Tetrachloroethylene, Tetrahydrofuran (THF), Thiophene, Trichloroethane, Trichloroethylene, Turpentine, Urea, Uric acid, Valeric acid, Valeric aldehyde, Varnish fumes, Vinegar, Vinyl acetate, Vinyl chloride monomer , Xenon delay, Xylene

Acetic acid, Acetone, Acrolein, Blood odour, Butadiene, Butyraldehyde, Chlorine, Chloromethane, Combustion odours, Dichloromonofluoromethane, Dimethyl sulphide, Ether, Ethyl alcohol, Ethyl chloride, Ethyl formate, * Ethyl mercaptan, Fumes, Hexane, Hexene, Hexyne, * Hydrogen iodide, * Hydrogen sulphide, Methyl acetate, Methyl alcohol, Methyl bromide, Methyl chloride, Methyl Ether, Methyl formate, Nitromethane, Para-dichloro benzene, Pentane, Pentylene, Pentyne, Phosgene, Propionaldehyde, Rubber, * Sewer odours, Slaughtering odours

Acetaldehyde, Acetonitrile, Acetylene, * Amines, Butane, Butylene, Carbon dioxide, * Corrosive gases, Ethylene oxide, * Formic acid, * Hydrogen bromide, * Hydrogen chloride, * Hydrogen fluoride, * Hydrogen selenide, * Methyl mercaptan, Nitric acid, Nitrogen dioxide, Propane, Ripening fruits, * Sulphur dioxide, * Sulphur trioxide, * Sulphuric acid

* Ammonia, Carbon monoxide, Ethane, Ethylene, * Hydrogen, * Hydrogen cyanide, * Mercury vapours, Methane

About SbyD

SbyD is a team of expert laboratory engineers, who have a rich experience in laboratory design and execution- be at R&D, QC, Application or Process Development lab. We have worked with food, pharma, chemical, automotive, educational, research, biotech, CRO labs and have good exposure to the typical lab equipments & work practices. We also understand global standards like GLP, OSHA, SEFA, ASHRAE, ANSI, NFPA very well and adopt those in our designs to build high quality & energy efficient labs.