Products

Safe and reliable lab equipment

Aero Equipment Enclosures

by SbyD

Aero Enclosures are widely used for Rotavapours, Weighing Balances, Microscopes, Aerosol Testing, and Sample Preparation.

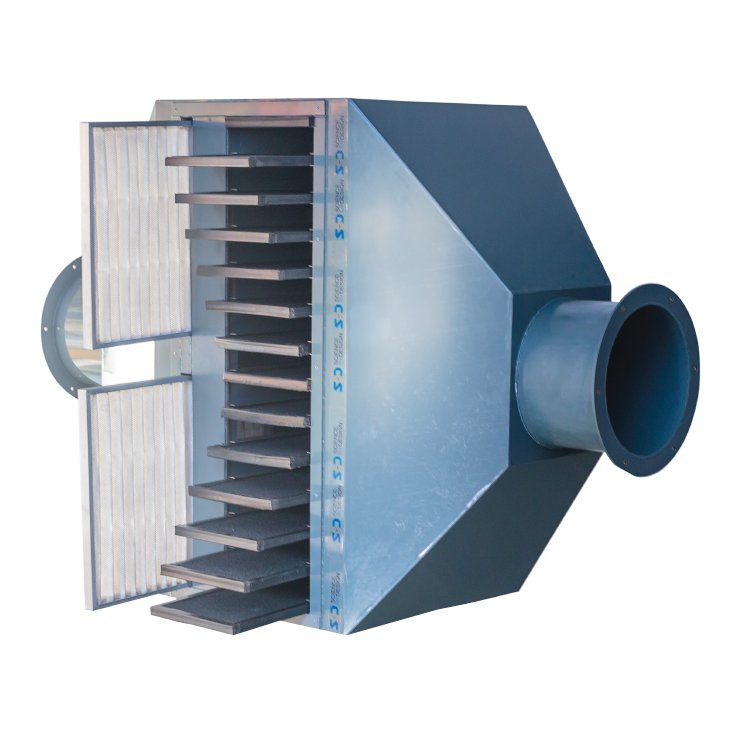

Aero Dry Scrubber

by SbyD

Aero Dry Scrubber is specifically designed for research laboratories having multiple fume hoods.

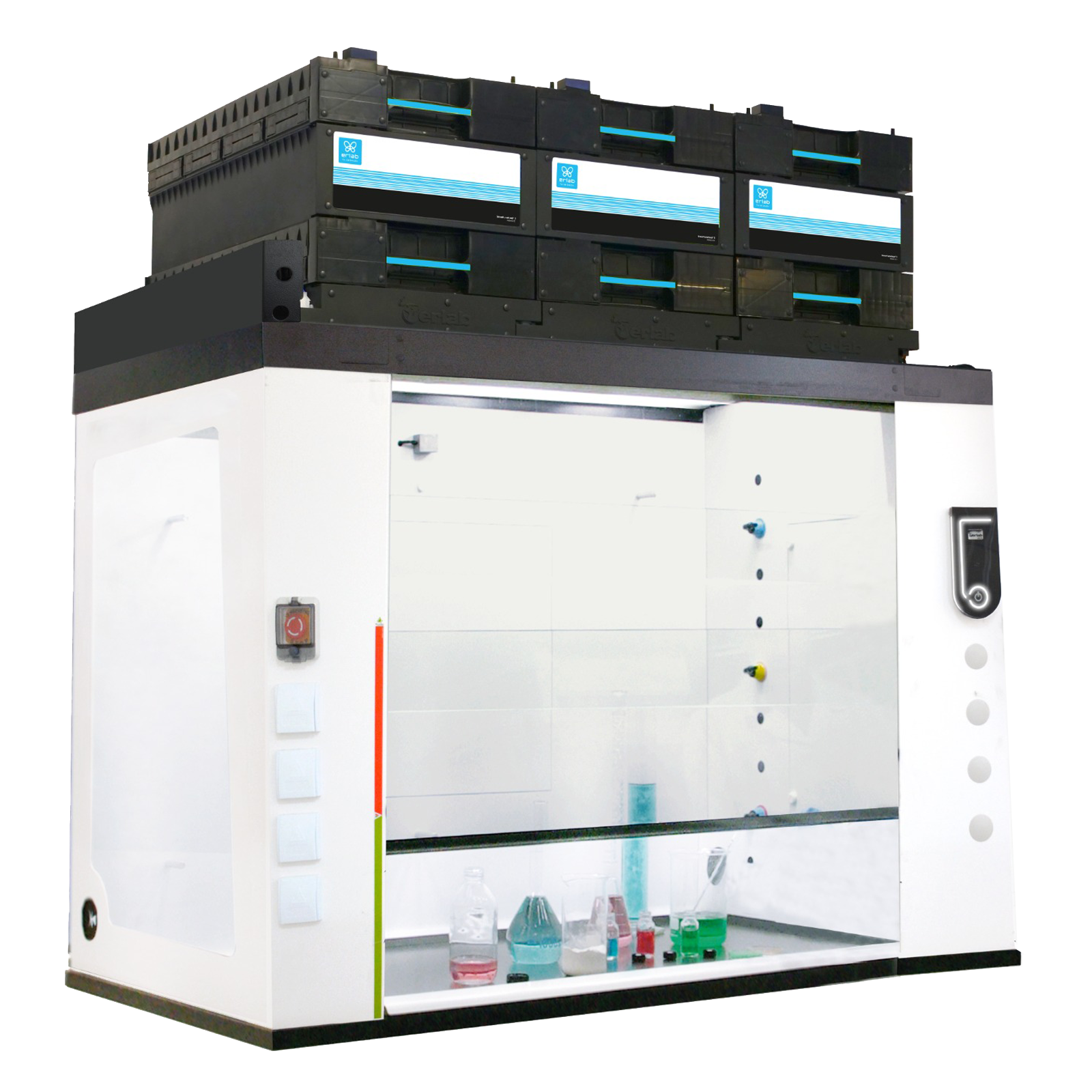

Ductless Filtration Solutions

by Erlab

Safety Showers

by BROEN-LAB

BROEN-LAB emergency showers and eye washers meet the European Committee Standardization requirements DS/EN 15154 1 and 2.

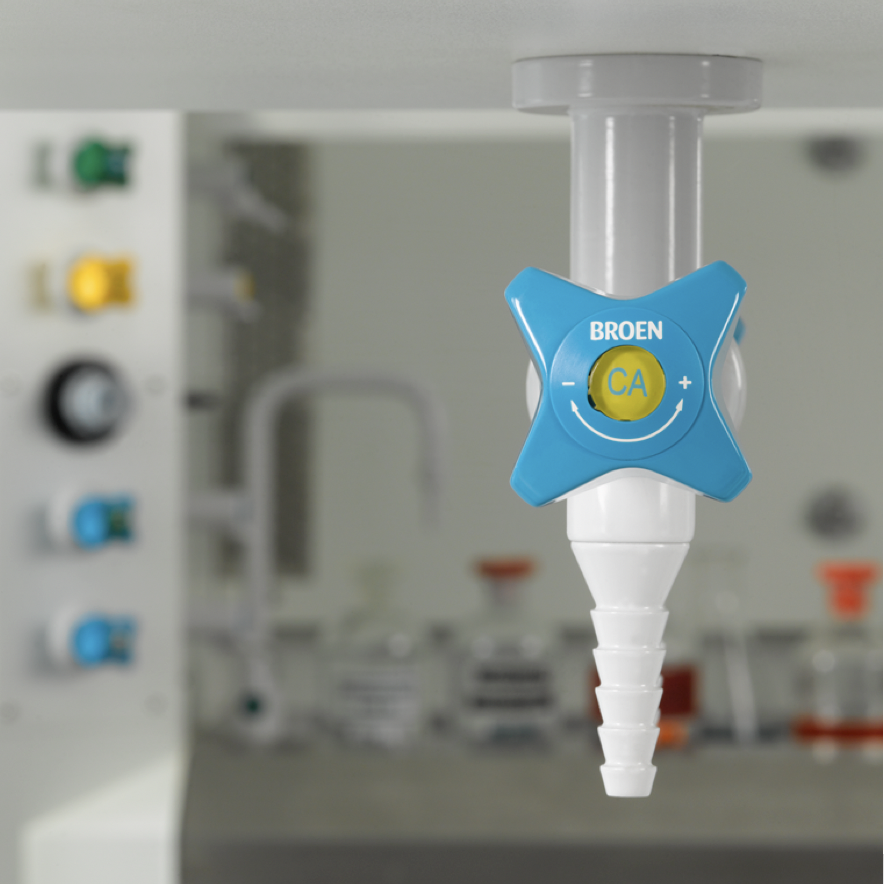

Lab Taps & Valves

by BROEN-LAB

BROEN-LAB’s extensive range of products covers the requirements of professional laboratories in most industries and in the educational sector.

VAV Controls

by TEL

TEL VAV controls are designed specifically to provide energy efficiency and ensure the safety of users working with fume hoods.

PP Blowers

by SEAT

SEAT Polypropylene Blowers are high-efficiency, easy-to-install solutions designed for highly corrosive environments.

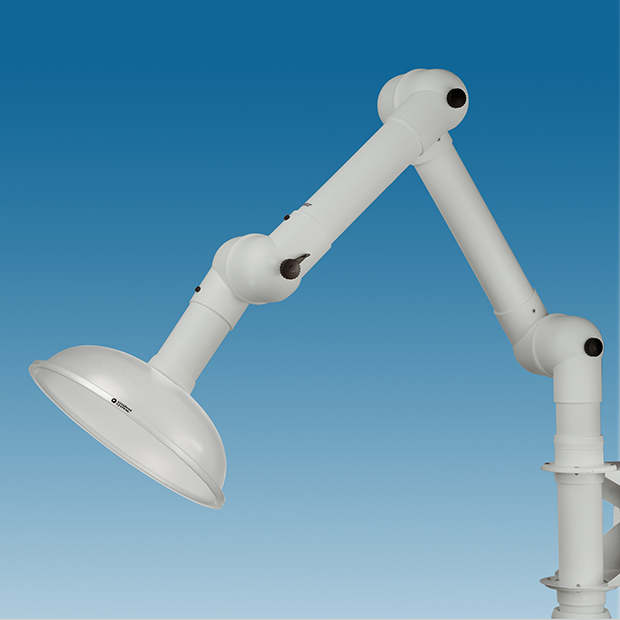

Spot Extractors

by Alsident Systems

Alsident Systems’ extraction arms are engineered for high durability with aluminum or polypropylene construction and feature a unique airflow-efficient damper design.

Lab Surfaces

by TRESPA® TOPLAB®

TRESPA® TOPLAB offers high-performance laboratory surfaces known for their exceptional chemical resistance, durability, and ease of cleaning.

Safety Cabinets

by Labor Security System

Labor Security System offers a wide range of safety cabinets for flammable and non-flammable liquid substance and gases.

Neutro Neutralization Tank

by SbyD

Neutro Neutralization Tank is designed to normalize the pH level of acidic water before being discharged into the drain pipe.