Research is a serious work and fume hood is a very important piece of this work. Often times, scientist/ project managers tell us, that their labs are very safe to work, because they think:-

- They have one of the finest branded fume hoods for their labs.

- All fume hoods have expected face velocity at safe opening height.

However above 2 conditions does not mean that your labs are safe for researchers. Fume hood without its exhaust system is just a box. Its performance depends on many internal and external factors. It is observed that around 15-30% fume hoods fail to pass ASHRAE 110: 2016 site performance tests. Let that be any brand then!

You need to be aware of several equally important factors which directly impact fume hood performance and user safety. I have captured all those 5 important factors in descending order:-

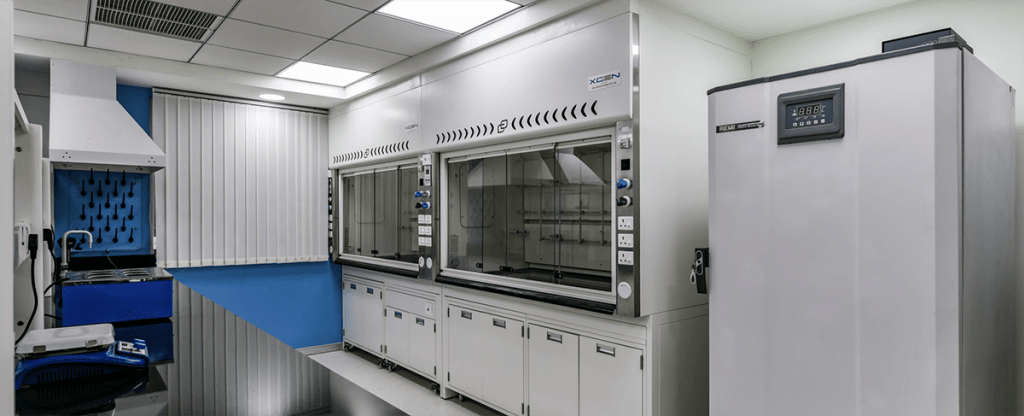

Fume hood design:

Fume hood is meant for smooth exhaust of the flow without any reverse flow towards the user. Hence, it is imperative that the fume hood design has to be very aerodynamic: i.e. the airfoil has a right aerodynamic shape to allow proper airflow below/above it; when the sash is fully closed. The sash handle should be aerodynamic to avoid eddy currents, baffle arrangement should facilitate immediate fume hood exhaust, exhaust port should have right size, corner posts should be aerodynamic, and the bypass arrangement of the fume hood should have right design. Each and every element mentioned above contributes a lot towards a safe fume hood design.

An incorrect design of fume hood is a disaster in waiting!

Supply air:

Lab supply air should be lesser than exhaust air to keep labs under negative pressure. Otherwise, it will impact fume hood performance too.

Also, supply air diffusers should be at least 5 feet (1.5 meter) away from fume hood sash plane. One should choose low velocity diffusers to avoid any turbulence in the fume hood flow. Draft of supply air should not be directed on the face of fume hood. This directly impacts the fume hood flow and the fume leakages can increase.

Also ensure that cross drafts within the room are below 30 fpm (0.15 m/s). There should not be any ceiling fan near the fume hood. It will affect the air entering the fume hood causing leakages.

Exhaust system:

If fume hood is a body, then exhaust blower is a heart and ductwork is like blood veins. A right sizing of blower & ductwork is very important for smooth flow. Blower capacity determines the fume hood face velocity. One small change in the position of dampers (fume hood dampers, branch dampers, bypass dampers) installed in the ductwork can impact the fume hood flow.

A Variable Air Volume system has many electromechanical components. Our experience shows that due to heavy wear & tear; VAV components start failing in 3 to 5 years. This might go un-noticed, in case if you do not have robust maintenance program.

Exhaust stack design:

A bad exhaust stack design will not only spread the fumes in the surrounding areas, but it will also bring back the chemical fumes back to your lab. Many labs in densely populated areas suffer from this problem today.

It is important to use a high height stack (as per local pollution control board rules). A safe bet will be to keep it at least 10 feet (3 meter) above the roof level of the building. Also, never place a supply AHU in the close vicinity of the exhaust stack. These might short circuit the air and bring back the chemical fumes to your lab.

User work practices:

This is one of the most important factors affecting a fume hood performance and user safety. Some common incorrect practices which affect fume hood airflow:-

- Lab equipment loading inside the hood; blocking its airfoil and baffles.

- Keeping sash open often above safe opening height

- Putting head inside the hood

- Ignoring the airflow alarm for low/high flow.

Any of the above actions will leak fail the very purpose of the hood and will expose the user directly to the fumes.

Even if you get the best fume hood in the world and design the best exhaust and lab supply air systems; you can’t protect people who follow incorrect and unsafe work practices.

These are the 5 topmost important factors which directly affect the performance of your fume hoods. So if think you need guidance to select a complete and good fume hood-exhaust system or if you want to evaluate the performance of your existing fume hoods; please feel free to write to us at: [email protected]